For over fifty years, we have been manufactoring and designing plastic materials, producing polypropylene pipes and fittings, and polyethylene drip irrigation systems.

Our primary objective has always been to create products entirely ‘Made in Italy’, technologically advanced, and reliable, capable of meeting the technical and operational needs of the market. Our long industrial experience, continuous investments in new technologies, the quality of raw materials, modern production facilities, and organizational flexibility are certainly the factors that have contributed to our success in Italy and around the world.

Rigorous controls are carried out along the entire production chain, from the acceptance of raw materials to the inspection of packaging and shipping in order to guarantee maximum reliability and quality in compliance with the most important international standards.

We have an in-house laboratory with highly advanced machinery that allows us to daily verify the quality of production through tensile and burst tests, pressure tests, , etc. and to continuously improve our products, exploring new and innovative solutions.

Additionally, we rely on independent testing bodies to guarantee and certify the quality of our products.

The high quality of our product, stemming from the use of certified raw materials and our company’s production process, ensures that our products are characterized by longlasting performance and also by high environmental and social compatibility. The raw material is recyclable, allowing it to be used for the creation of new products, and our production system is continuously monitored and optimized to reduce energy consumption.

The environmental compatibility test is verified by several research organizations and institutions. It is carried out on the raw material, and also on all its additives (pigments, color stabilizers, etc.), in order to exclude the presence of heavy metals or of elements hazardous to health.

Toro 25 system consists of polypropylene copolymer random (PP-R) pipes and fittings with high physical and mechanical properties, designed for the conveyance of pressurized fluids.

The raw material used (PP-R 100 and PP-R 125) is certified for the conveyance of fluids intended for human consumption, making our products resistant to high temperatures and pressure, classifying them as a modern alternative to traditional metallic materials.

Toro 25 system pipes and fittings can be used for the transportation of hot/cold water, drinking water, wastewater and chemicals, heating and cooling systems, in civil, commercial, industrial, and naval sectors.

Throughout all production stages, rigorous procedures are applied to ensure the maximum reliability and quality of our products. They are periodically subjected to tests in our in-house laboratory and by external organizations to ensure, certify, and recognize the system’s reliability. Toro 25 products are manufactured in compliance with German standards DIN 8077-78 and international standards ISO 15874 – ISO 15494.

Compliance with standards is guaranteed by constant monitoring from international product certification bodies, of which Toro 25 holds the conformity marks.

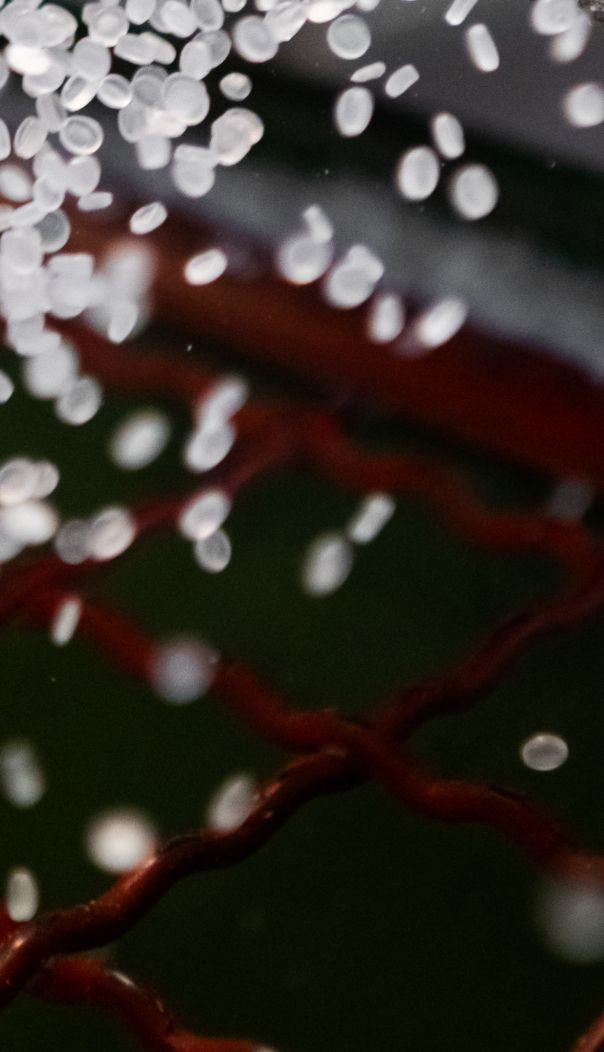

Pluvio drip irrigation systems are made on top quality flexible polyethylene pipes which guarantee maximum reliability over time and the best performance in terms of mechanical resistance and elongation. These micro-flow irrigation systems allow the water to be localized close to the plant and its

root system, improving the wellbeing of the plant with significant water and fertilizers saving.

The different types of drippers are designed in order to guarantee a high turbulence of the water flow, a perfect dripping along all sections of use and to satisfy the needs of different crops and types of soil.

Pluvio drip irrigation systems can be used for the irrigation of open field crops, tree crops, protected crops, sub-irrigation and fertirrigation. They represent the ideal solution to guarantee a correct water supply, reducing waste and maximizing efficiency: choosing a quality drip irrigation system means guaranteeing your cultivation a constant and regular water supply,

with consequent benefits in terms of health and plant growth.

During all production phases, are applied rigorous procedures to ensure maximum reliability and quality of our products. They are cyclically subjected to tests and checks in order to guarantee and recognize the reliability of the systems.

produced every year

systems built all over the world

COUNTRY

customer service

Subscribe now to our newsletter:

Advanced Plastic Technologies

Viale dell’Industria, 3 – 76121 Barletta (BT)

Tel: +39 0883 533167

Fax: +39 0883 337877

P.IVA 03897720722

REA 282055

Site created by Keyword